|

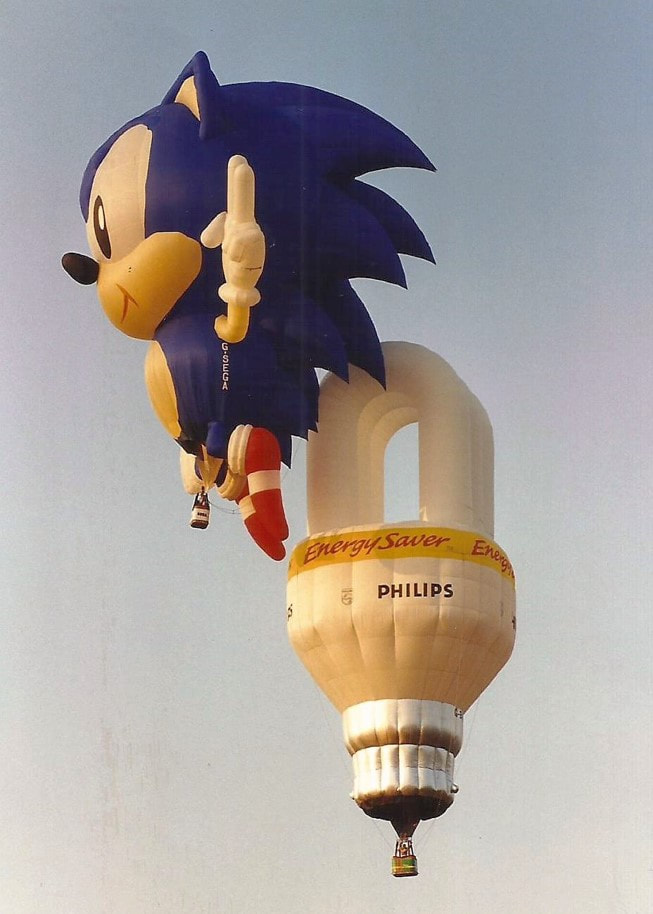

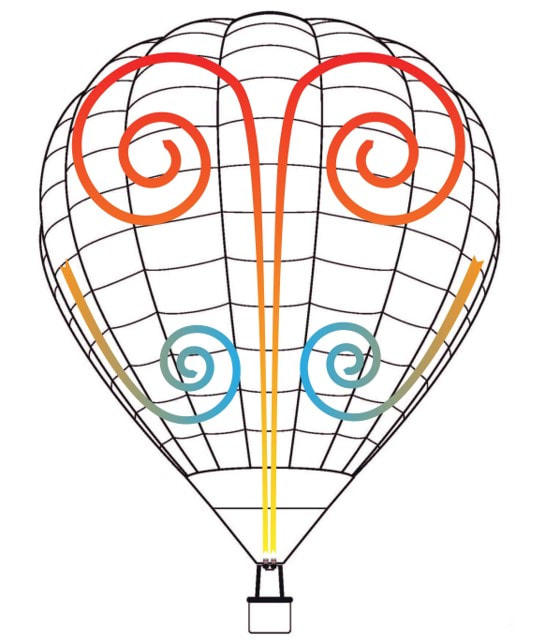

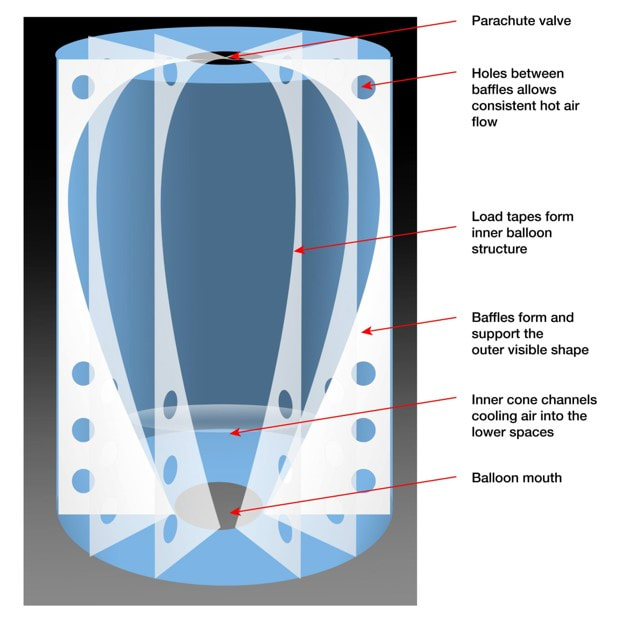

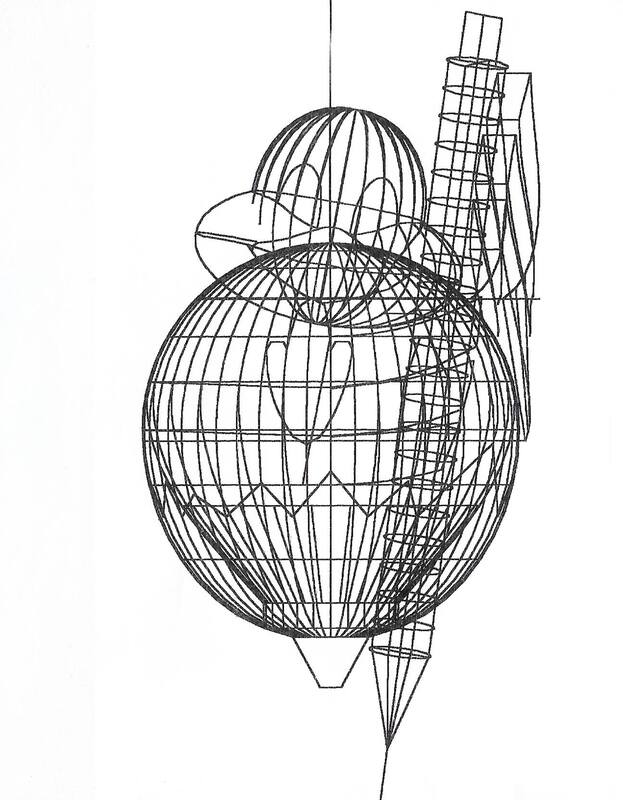

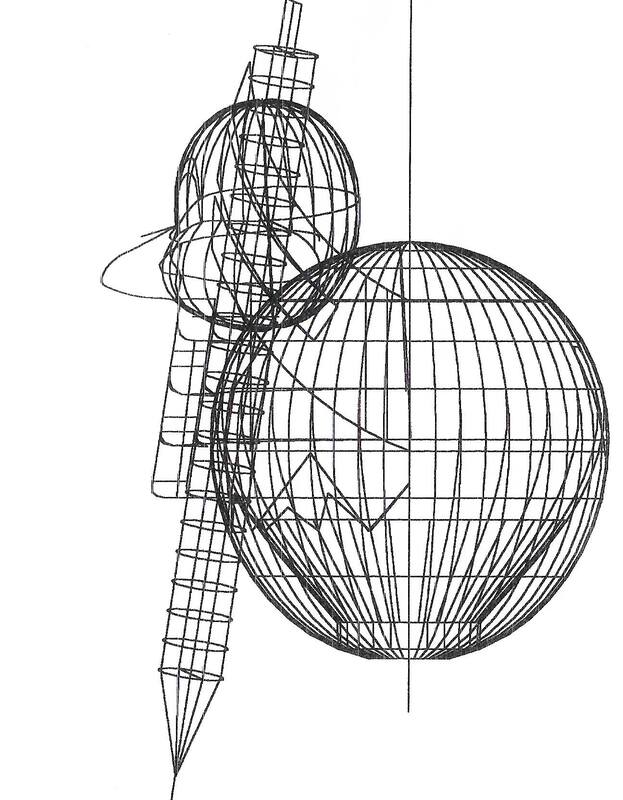

Read all about how a special shape hot air balloon comes to life in our latest blog written by ex VABC creative director Mark Lockwood, who has designed many classic shapes himself such as Action Man, the Tesco trolley and Cadbury's caramel bunny. It's not as easy as you might think... When asked if I could write something about how to design a special shape balloon, my first thought was that this would be like asking “How long is a piece of string?” as there is no hard and fast rules, but when I thought about it a little more, I realised there are some basic tenets that need to be followed to create something eye-catching and, most importantly, flyable. Another problem is that there is a danger it can get very technical because the engineering involved covers everything from thermal and fluid dynamics to complex load and stress calculations. By definition, a special shaped balloon diverges from the standard inverted teardrop in some way or another and falls into the categories of either a standard balloon with add-ons, such as the Son of the Pink Panther, or a free-form like The Cadburys Caramel Bunny and many of the popular product replicas and characters. So what actually goes into the process of designing one? This is going to depend upon whether you are designing it for everyday commercial use or as a once in a while, with lots of willing helpers, private indulgence. Muir Moffat’s Scottish piper is an example as are the amazing collection of shapes commissioned and flown by the late Malcolm Forbes. Due to the cost of construction compared to its standard brethren, the majority over the years have been designed as giant flying advertising billboards and funded from corporate coffers rather than by individuals with very deep pockets. If you want to stand out in a crowd of ordinary balloons at an event or make a super-sized brand statement, then a special shape is just the tool to do the job, but be prepared to work very, very hard! Quite often a designer will just take an image of a product or an object and stick a basket underneath it without considering how it would be built or even what it might look like from another angle. Over the years we learned many sometimes expensive lessons when it came to making mistakes and these have led to the process being much more exact and fault free these days. With current CAD techniques, it is possible to calculate the exact panel shapes required to create a three dimensional object, including all the inner support panels and baffles to hold it together and these go directly to a computer controlled cutting table. The giant jigsaw puzzle that emerges still needs to be carefully sewn together by hand using miles of thread and the skilled eyes and hands of a seamstress. So, let’s start with the standard balloon. Form follows function here because the shape of the balloon envelope is designed to capture the maximum volume of hot air where it is most efficient at creating lift: at the top. This puts the least stress on the fabric and structure and also safely supports the basket, burners, fuel and passengers. That bubble of hot air is fed from the burners, a little like a mini thermal rising from the ground, and heats the air at the top, slowly cooling and then falling back down the inner sides of the balloon to be re- heated and shoot to the top again. This hot air has a slightly higher pressure however is less dense than the air outside the balloon, which is the basic principle of why it rises and how we are able to fly. The individual fabric panels of a balloon are all held together with tough nylon straps (Load Tapes) that run from the top of the envelope to the mouth to create a super strong net to support the basket. If we make a hole in one of the panels, the hot air will escape but not affect the integral ‘skeleton’ of these load tapes. Creating a ‘blister’ where the hole is, the escaping hot air will inflate it and thus we have our add-on shape. If we also extend the distance from the bottom of the balloon envelope, this colder air filled section can also be a part of the structure. This is the way the first special shape, The Robertson’s Golly, was designed. Some examples of add-on special shapes; Radio 1 DJ, Mercury and Son of the Pink Panther Once you step away from the familiar tear-drop shape, things can get a little more complex. The formula is quite simple, the volume inside whatever the shape must be sufficient to provide lift for the weight of all the fabric and the basket and fuel. The simplest solution is therefore to try and incorporate the internal skeletal structure of a standard balloon if possible, even if it is just the load tapes and all the rest of the shape is just made up of fabric panels. Simple shapes like cans, bottles, jars, balls all use this principle as they are what we call ‘axi-symmetrical’ and can be rotated around a central vertical axis. The recent development of Racer balloons, which are more ‘rugby ball’ shaped, gives a little more flexibility for the designer to incorporate that into a shape as well. When it goes completely ‘off the park’ is when there is a shape that does not seem to have a natural balloon space to fit inside. Here is where the engineers get involved as it is necessary to calculate the amounts of load created by each part of the balloon on the integrity of the whole structure. If there is too much force or strain in any one direction, this causes a weakness and can cause a catastrophic failure, which is not good. Once again the whole thing comes down to making sure there are smooth lines of load carrying from the top of the balloon to the basket as well as trying to hold the external shape together. By cutting the fabric panels in the right way, like making a sculpture, the shape will support itself but careful consideration has to be given to any un-even stress. As the pressure is from the inside, it’s possible to support the outer fabric layer with baffles and formers but the flow of hot air into any appendages needs careful calculation. Anything below the equator will need to have ways to trap the air inside as it cools. This then creates another operational issue of how to get the air back out again when the balloon lands. Once on the ground, any wind will cause the envelope to continue dragging until sufficient hot air has been released so the use of ‘one shot’, Velcro sealed rip panels has been developed. Often these are positioned in the hottest, and therefore highest load, areas of the envelope and need to be carefully closed and locked with a breakable cotton thread before flight. When the pilot has committed to a landing, they are armed with a sharp tug on a rope and then pulled open to allow as much air out as possible in the shortest time. Smaller non structural Velcro sealed openings are then included in the various appendages to aid the deflation once the balloon has finally come to rest and then comes the long and hard work of returning the balloon envelope into its bag. Because of the size and the additional amounts of material used, special shapes tend to be much heavier than their standard counterparts. A standard 90,000 cubic foot envelope weighs around 70 kilos, a simple shape of the same volume can weigh up to 250kgs. As a designer, the process starts with looking at the product or shape to be promoted and then trying to work out if a balloon structure can be fitted inside it. If that is possible then we can move on to looking at the various angles the final design will be seen from and where the main branding will need to be placed. From a commercial perspective it is also essential at this point to look at the operational efficiency of the shape. How will it react in the wind when tethered? How easy will it be to fly and, most particularly, land? How many crew will be needed bearing in mind how heavy it may be and what vehicle and trailer will it fit into? If there is no obvious shape solution, the next stage is to try and find a way to integrate the product into a viable option. An example here is the Bic Chick. The product itself, the Soft Feel pen, was not a viable shape on its own as it would be too thin to provide enough volume for lift. By using the chick character from the TV advertising that was running at the time as the main part of the balloon and building in the pen, it solved both the operational problem and maximised the branding options for the client. The wireframe designs show how the various parts of the structure fit together as well as much of the inner baffles required to keep the lower part pressurised. The Bic chick special shape and wireframe design images Once you have your special shape, do you need any special qualifications to fly it? Once in the air they fly in exactly the same way as a standard balloon but with little individual idiosyncrasies. There is a tendency to rotate on climb and descent, which can mean having to move around the basket a lot to make sure you can see where you are going and some have bits hanging down below the burner so you need to keep an eye on these. Being heavier than normal balloons, they can cool and descend much faster and some have the unnerving habit of reacting very slowly on cooling at first and then suddenly dropping out of the sky! The biggest thing you need is experience. As the majority are advertising a product, a commercial balloon pilots license is needed with lots of flying hours and even more tethering as they spend more time static displaying than free flying. This experience counts when it comes to making the decision to fly based on the weather conditions as the inflation, launch and landing are those needing ‘positive decision making’. The reward is often the reaction of a crowd or an individual landowner when a giant character or product appears in their field. Next time you see one of these giant flying sculptures, think of the skills of the people needed to make it possible from the designers concept through to the engineers, the seamstresses, the artists adding the painted details and finally the pilots and incredibly hard working crews who make it all possible. Read more about special shape balloons You can discover lots more about the world of special shape hot air balloons on MJ Ballooning by visiting our Bristol special shapes page, blogs and watching our videos on YouTube. Thanks to Ballooning Pictures UK for providing some of the older photos - G-BUNI, G-SEGA & G-BVWI, G-OIFM, G-PINX, G-BYEI.

|

BlogWelcome to MJ Ballooning's blog! Read about local goings on, special shapes and more.

Categories

All

Archives

July 2024

|

|

|

- Home

- Our Balloons

- 2024 Season

- Special Shapes

-

Gallery

-

Bristol Balloon Fiesta

>

- 2023 Fiesta

- 2022 Fiesta

- 2021 Fiesta

- 2020 Fiesta

- 2019 Fiesta

- 2018 Fiesta

- 2017 Fiesta

- 2016 Fiesta

- 2015 Fiesta

- 2014 Fiesta

- 2013 Fiesta

- 2012 Fiesta

- 2011 Fiesta

- 2010 Fiesta

- 2009 Fiesta

- 2008 Fiesta

- 2007 Fiesta

- 2006 Fiesta

- 2005 Fiesta

- 2004 Fiesta

- 2003 Fiesta

- 2002 Fiesta

- 2001 Fiesta

- 2000 Fiesta

- 1998 Fiesta

- 1990 Fiestas >

- 1990 Fiesta

- 1990s Night Glows

- Late 1980s

- 1988 Fiesta

- 1983 Fiesta

- 1981 Fiesta

- Mixed Fiesta Photos

-

2024 Bristol & Bath Flights

>

- 14/01/24 - Maize Field Tether AM

- 03/03/24 - Rupert Bear Inflation at Snake Meadows AM

- 13/04/24 - Ashton Court AM

- 14/04/24 - Flight from Saltford PM

- 20/04/24 - Bristol Balloon Collectors Inflation Day

- 20/04/24 - Saltford PM

- 23/04/24 - Royal Victoria Park PM

- 24/04/24 - Flight from Saltford PM

- 04/05/24 - Flight from Ashton Court AM

- 04/05/24 - Maize Field PM

- 05/05/24 - Flight from Maize Field AM

- 07/05/24 - Royal Victoria Park PM

- 08/05/24 - Ashton Court PM

- 09/05/24 - Saltford PM

- 10/05/24 - Snow White Inflation at Ashton Court PM

- 11/05/24 - Michelin Man Inflation at Snake Meadows PM

- 11/05/24 - Light Up Snake Meadows

-

2023 Bristol & Bath Flights

>

- 28/01/23 - FT Newspaper Special Shape Inflation at Henbury AM

- 04/03/23 - Clutton AM

- 05/03/23 - Joycam Lips & Orange Special Shape Inspections AM

- 19/03/23 - Ashton Court Tether PM

- 07/04/23 - Ashton Court AM

- 07/04/23 - Ashton Court Tether PM

- 08/04/23 - Royal Victoria Park PM

- 08/04/23 - Maize Field PM

- 16/04/23 - Maize Field PM

- 25/04/23 - Royal Victoria Park PM

- 30/04/23 - Maize Field AM

- 01/05/23 - Ashton Court PM

- 07/05/23 - Ashton Court PM

- 11/05/23 - Ashton Court AM

- 16/05/23 - Ashton Court PM

- 17/05/23 - Ashton Court PM

- 18/05/23 - Ashton Court AM

- 18/05/23 - Royal Victoria Park PM

- 19/05/23 - Snow White Special Shape Inflation at Ashton Court PM

- 23/05/23 - Flight from Maize Field PM

- 24/05/23 - Ashton Court AM

- 27/05/23 - Bath Balloon Fiesta | Hinton Charterhouse AM

- 27/05/23 - Bath Balloon Fiesta | Royal Crescent PM

- 14/06/23 - Newbridge PM

- 17/06/23 - Tuckers Grave Flyout PM

- 19/06/23 - Ashton Court PM

- 21/06/23 - Ashton Court PM

- 23/06/23 - Ashton Court PM

- 24/06/23 - Redcatch Park Flyout PM

- 09/07/23 - Ashton Court AM

- 17/07/23 - Royal Victoria Park PM

- 18/07/23 - Ashton Court AM

- 03/08/23 - Ashton Court AM

- 04/08/23 - Royal Victoria Park PM

- 06/08/23 - Ashton Court AM

- 09/08/23 - Royal Victoria Park PM

- 15/08/23 - Ashton Court PM

- 16/08/23 - Maize Field PM

- 23/08/23 - Keynsham PM

- 25/08/23 - Ashton Court AM

- 28/08/23 - Action Man Special Shape Test Inflation at Ashton Court PM

- 02/09/23 - Royal Victoria Park PM

- 03/09/23 - Action Man Special Shape Inflation at Ashton Court PM

- 14/09/23 - Ashton Court PM

- 15/09/23 - Flight from Royal Victoria Park PM

- 25/09/23 - Ashton Court PM

- 08/10/23 - Ashton Court AM

- 08/10/23 - Sonic the Hedgehog Special Shape Inflation at Ashton Court PM

- 22/10/23 - Slither the Snake Inflation at Royal Victoria Park PM

- 03/11/23 - Bath Racecourse Fireworks

-

2022 Bristol & Bath Flights

>

- 12/01/22 - Ashton Court AM

- 15/01/22 - Ashton Court AM

- 16/01/22 - Ashton Court AM

- 23/01/22 - Ashton Court AM

- 30/01/22 - Ashton Court AM

- 11/02/22 - Ashton Court AM

- 04/03/22 - Ashton Court AM

- 14/03/22 - Ashton Court AM

- 15/03/22 - Ashton Court AM

- 20/03/22 - Orange Inflation at Ashton Court PM

- 24/03/22 - Ashton Court AM

- 02/04/22 - Royal Victoria Park AM

- 08/04/22 - Ashton Court AM

- 09/04/22 - Ashton Court AM

- 10/04/22 - Maize Field AM

- 10/04/22 - Ashton Court PM

- 13/04/22 - Ashton Court PM

- 14/04/22 - Joycam Lips Flight from Ashton Court PM

- 15/04/22 - Special Shape Tether at Ashton Court

- 15/04/22 - Maize Field PM

- 16/04/22 - Joycam Lips Flight from Maize Field PM

- 18/04/22 - Ashton Court AM

- 25/04/22 - Royal Victoria Park PM

- 28/04/22 - Newbridge PM

- 29/04/22 - Royal Victoria Park PM

- 30/04/22 - Maize Field AM

- 30/04/22 - Ashton Court Tether

- 30/04/22 - Joycam Lips Flight from Ashton Court PM

- 05/05/22 - Ashton Court AM

- 07/05/22 - Maize Field PM

- 08/05/22 - Maize Field Tether

- 08/05/22 - Maize Field PM

- 12/05/22 - Ashton Court AM

- 14/05/22 - Ashton Court AM

- 14/05/22 - Maize Field PM

- 19/05/22 - Ashton Court AM

- 19/05/22 - Ashton Court PM

- 21/05/22 - Ashton Court PM

- 27/05/22 - Ashton Court AM

- 28/05/22 - Maize Field AM

- 28/05/22 - Bath Balloon Fiesta | Royal Crescent PM

- 29/05/22 - Bristol Balloon Tether at Ashton Court AM

- 13/06/22 - Ashton Court AM

- 13/06/22 - Ashton Court PM

- 14/06/22 - Flight from Ashton Court AM

- 14/06/22 - Ashton Court PM

- 15/06/22 - Ashton Court PM

- 16/06/22 - Ashton Court AM

- 16/06/22 - Ashton Court PM

- 20/06/22 - Orange Inflation at Ashton Court PM

- 21/06/22 - Royal Victoria Park PM

- 22/06/22 - Ashton Court AM

- 22/06/22 - Maize Field PM

- 22/06/22 - Newbridge PM

- 23/06/22 - Ashton Court AM

- 03/07/22 - Ashton Court AM

- 05/07/22 - Ashton Court AM

- 06/07/22 - Ashton Court AM

- 07/07/22 - Keynsham PM

- 09/07/22 - Maize Field AM

- 09/07/22 - Keynsham AM

- 09/07/22 - Ashton Court PM

- 10/07/22 - Maize Field AM

- 10/07/22 - Special Shapes at Ashton Court PM

- 11/07/22 - Ashton Court PM

- 12/07/22 - Ashton Court PM

- 13/07/22 - Ashton Court PM

- 15/07/22 - Ashton Court PM

- 16/07/22 - Coffee Jar Flight from Norton St Philip PM

- 20/07/22 - Ashton Court AM

- 26/07/22 - Ashton Court PM

- 28/07/22 - Royal Victoria Park PM

- 29/07/22 - Ashton Court PM

- 05/08/22 - Ashton Court AM

- 06/08/22 - Maize Field AM

- 06/08/22 - Ashton Court PM

- 07/08/22 - Alien Inflation at Newton St Loe AM

- 07/08/22 - Ashton Court PM

- 08/08/22 - Ashton Court PM

- 12/09/22 - Royal Victoria Park PM

- 17/09/22 - Ashton Court PM

- 18/09/22 - Ashton Court AM

- 18/09/22 - Royal Victoria Park PM

- 19/09/22 - Keynsham PM

- 21/09/22 - Ashton Court PM

- 08/10/22 - Ashton Court AM

- 08/10/22 - Ashton Court PM

- 19/11/22 - Ashton Court AM

- 10/12/22 - Ashton Court AM

- 10/12/22 - Ashton Court Tether PM

- 16/12/22 - Ashton Court AM

-

2021 Bristol & Bath Flights

>

- 02/01/21 - Ashton Court AM

- 27/02/21 - Ashton Court AM

- 07/03/21 - Ashton Court AM

- 08/03/21 - Ashton Court PM

- 30/03/21 - Ashton Court AM

- 30/03/21 - Ashton Court PM

- 31/03/21 - Ashton Court PM

- 04/04/21 - Ashton Court AM

- 12/04/21 - Ashton Court PM

- 13/04/21 - Ashton Court AM

- 13/04/21 - Ashton Court PM

- 14/04/21 - Ashton Court AM

- 14/04/21 - Royal Victoria Park PM

- 16/04/21 - Royal Victoria Park PM

- 17/04/21 - Ashton Court AM

- 17/04/21 - Maize Field PM

- 18/04/21 - Maize Field AM

- 18/04/21 - Maize Field PM

- 19/04/21 - Royal Victoria Park PM

- 20/04/21 - Maize Field PM

- 26/04/21 - Royal Victoria Park PM

- 27/04/21 - Ashton Court AM

- 02/05/21 - Ashton Court AM

- 02/05/21 - Ashton Court Tether AM

- 07/05/21 - Ashton Court AM

- 07/05/21 - Maize Field Tether

- 17/05/21 - Ashton Court AM

- 27/05/21 - Ashton Court AM

- 27/05/21 - Ashton Court PM

- 27/05/21 - Maize Field PM

- 28/05/21 - Ashton Court PM

- 29/05/21 - Maize Field PM

- 30/05/21 - Royal Victoria Park PM

- 31/05/21 - Maize Field AM

- 04/06/21 - Ashton Court AM

- 07/06/21 - Royal Victoria Park PM

- 08/06/21 - Ashton Court PM

- 09/06/21 - Ashton Court AM

- 12/06/21 - Bath Balloon Fiesta | Inglescombe Farm PM

- 13/06/21 - Bath Balloon Fiesta | Glasshouse Playing Fields AM

- 13/06/21 - Bath Balloon Fiesta | Glasshouse Playing Fields PM

- 14/06/21 - Ashton Court AM

- 15/06/21 - Ashton Court PM

- 16/06/21 - G-LIPS Tether at Ashton Court PM

- 17/06/21 - Ashton Court PM

- 23/06/21 - Ashton Court AM

- 23/06/21 - Ashton Court PM

- 26/06/21 - G-DIPI Tether at Ashton Court PM

- 30/06/21 - Ashton Court PM

- 01/07/21 - Ashton Court PM

- 02/07/21 - Poplar Insulation Tether at Ashton Court AM

- 02/07/21 - Ashton Court PM

- 08/07/21 - Ashton Court PM

- 09/07/21 - Ashton Court AM

- 10/07/21 - Keynsham PM

- 14/07/21 - Ashton Court AM

- 14/07/21 - Royal Victoria Park PM

- 15/07/21 - Royal Victoria Park PM

- 16/07/21 - Keynsham PM

- 17/07/21 - Royal Victoria Park PM

- 17/07/21 - Maize Field PM

- 18/07/21 - Maize Field AM

- 18/07/21 - Special Shape Tether at Ashton Court PM

- 19/07/21 - Ashton Court PM

- 20/07/21 - Royal Victoria Park PM

- 21/07/21 - Maize Field PM

- 22/07/21 - Royal Victoria Park PM

- 25/07/21 - Ashton Court PM

- 26/07/21 - Ashton Court AM

- 01/08/21 - Ashton Court AM

- 01/08/21 - Ashton Court PM

- 03/08/21 - Royal Victoria Park PM

- 12/08/21 - Dundridge Park AM

- 22/08/21 - Ashton Court PM

- 23/08/21 - Maize Field PM

- 25/08/21 - Royal Victoria Park PM

- 27/08/21 - Maize Field AM

- 03/09/21 - Royal Victoria Park PM

- 04/09/21 - Maize Field PM

- 05/09/21 - G-LIPS Flight | Maize Field PM

- 12/09/21 - Maize Field AM

- 14/09/21 - Keynsham PM

- 14/09/21 - Royal Victoria Park PM

- 15/09/21 - Ashton Court PM

- 16/09/21 - Ashton Court PM

- 18/09/21 - J&B Bottle Special Shape Tether AM

- 20/09/21 - Royal Victoria Park PM

- 20/09/21 - Maize Field PM

- 21/09/21 - Keynsham PM

- 21/09/21 - Oakhill Recreational Ground, Radstock PM

- 06/10/21 - Ashton Court PM

- 07/10/21 - Ashton Court PM

- 08/10/21 - Ashton Court AM

- 08/10/21 - Royal Victoria Park PM

- 09/10/21 - Royal Victoria Park PM

- 10/10/21 - Royal Victoria Park PM

- 10/10/21 - Keynsham PM

- 11/10/21 - Ashton Court PM

- 12/10/21 - Keynsham PM

- 13/10/21 - Ashton Court PM

- 15/09/21 - Ashton Court AM

- 15/10/21 - Ashton Court PM

- 16/10/21 - Keynsham PM

- 17/10/21 - Ashton Court PM

- 14/11/21 - Ashton Court AM

- 19/12/21 - Ashton Court AM

- 26/12/21 - Ashton Court AM

-

2020 Bristol & Bath Flights

>

- 20/01/20 - Ashton Court AM

- 25/01/20 - Galleon Special Shape Tether AM

- 27/05/20 - Ashton Court AM

- 30/05/20 - Ashton Court AM

- 02/06/20 - Ashton Court AM

- 07/06/20 - Henbury Tether PM

- 24/06/20 - Ashton Court AM

- 24/06/20 - Henbury Tether PM

- 07/07/20 - Ashton Court AM

- 11/07/20 - Ashton Court AM

- 11/07/20 - Ashton Court PM

- 12/07/20 - Ashton Court AM

- 12/07/20 - Maize Field Tether

- 12/07/20 - Ashton Court PM

- 20/07/20 - Ashton Court PM

- 20/07/20 - G-GCCC Flight | Bristol County Ground PM

- 21/07/20 - Ashton Court PM

- 22/07/20 - Ashton Court AM

- 29/07/20 - Ashton Court AM

- 29/07/20 - Ashton Court PM

- 30/07/20 - Ashton Court AM

- 30/07/20 - Royal Victoria Park PM

- 30/07/20 - County Ground PM

- 02/08/20 - Ashton Court AM

- 04/08/20 - Ashton Court AM

- 07/08/20 - Ashton Court AM

- 07/08/20 - Henbury Night Glow

- 09/08/20 - Maize Field PM

- 27/08/20 - Ashton Court AM

- 30/08/20 - WRBBAC Flyout | Timsbury PM

- 31/08/20 - George Brazil Airship | Havyatt Green AM

- 31/08/20 - Maize Field PM

- 01/09/20 - Sky Orchestra | Ashton Court PM

- 06/09/20 - Key Worker Flight over Bristol AM

- 10/09/20 - Ashton Court AM

- 10/09/20 - Ashton Court PM

- 11/09/20 - Ashton Court AM

- 12/09/20 - Ashton Court PM

- 13/09/20 - Ashton Court PM

- 14/09/20 - Royal Victoria Park PM

- 15/09/20 - Ashton Court PM

- 21/09/20 - Ashton Court AM

- 21/09/20 - Ashton Court PM

- 22/09/20 - Ashton Court AM

- 28/09/20 - Ashton Court AM

- 28/09/20 - Bristol Balloon Tether | Ashton Court PM

- 29/09/20 - Wallace & Gromit Rocket Launch | Lloyds Amphitheatre AM

- 29/09/20 - Ashton Court PM

- 11/10/20 - Ashton Court PM

- 04/11/20 - Ashton Court AM

-

2019 Bristol & Bath Flights

>

- 27/02/19 - Ashton Court AM

- 27/02/19 - Ashton Court PM

- 01/03/19 - Ashton Court PM

- 20/03/19 - Ashton Court AM

- 24/03/19 - Maize Field AM

- 24/03/19 - Upper Swainswick AM

- 25/03/19 - Maize Field PM

- 26/03/19 - Royal Victoria Park AM

- 26/03/19 - Royal Victoria Park PM

- 27/03/19 - Ashton Court AM

- 28/03/19 - Wraxall PM

- 29/03/19 - G-UWEB Tether | Ashton Court PM

- 30/03/19 - Keynsham PM

- 01/04/19 - Royal Victoria Park PM

- 11/04/19 - Royal Victoria Park PM

- 12/04/19 - Royal Victoria Park PM

- 19/04/19 - Royal Victoria Park PM

- 19/04/19 - Maize Field PM

- 20/04/19 - Maize Field AM

- 20/04/19 - Royal Victoria Park AM

- 20/04/19 - WRBBAC Flyout | Maize Field PM

- 21/04/19 - Maize Field AM

- 21/04/19 - Royal Victoria Park AM

- 21/04/19 - Royal Victoria Park PM

- 21/04/19 - Maize Field PM

- 23/04/19 - Royal Victoria Park PM

- 28/04/19 - Ashton Court PM

- 29/04/19 - Ashton Court PM

- 30/04/19 - Ashton Court PM

- 05/05/19 - Maize Field AM

- 05/05/19 - Ashton Court PM

- 06/05/19 - Ashton Court PM

- 10/05/19 - Ashton Court AM

- 12/05/19 - Maize Field AM

- 12/05/19 - Royal Victoria Park PM

- 12/05/19 - Ashton Court PM

- 21/05/19 - Ashton Court PM

- 22/05/19 - Royal Victoria Park PM

- 24/05/19 - Ashton Court AM

- 25/05/19 - Ashton Court AM

- 25/05/19 - Bath Balloon Fiesta AM

- 31/05/19 - Ashton Court PM

- 01/06/19 - Shirehampton PBA Club Fun Day

- 06/06/19 - Ashton Court AM

- 09/06/19 - Ashton Court AM

- 18/06/19 - Ashton Court AM

- 21/06/19 - Ashton Court AM

- 21/06/19 - Ashton Court PM

- 22/06/19 - G-NORG Airship in Ashton Court AM

- 25/06/19 - Flight from Maize Field PM

- 02/07/19 - Flight from Maize Field PM

- 03/07/19 - Royal Victoria Park PM

- 04/07/19 - Ashton Court AM

- 04/07/19 - Ashton Court PM

- 04/07/19 - Longwell Green Tether PM

- 05/07/19 - Ashton Court AM

- 05/07/19 - Ashton Court PM

- 06/07/19 - Flight from Ashton Court AM

- 06/07/19 - Lawrence Weston Tether at LDubstock

- 07/07/19 - Maize Field AM

- 07/07/19 - Flight from Ashton Court PM

- 08/07/19 - Ashton Court PM

- 09/07/19 - Flight from Ashton Court PM

- 10/07/19 - Ashton Court PM

- 13/07/19 - Maize Field PM

- 14/07/19 - Royal Victoria Park PM

- 15/07/19 - Ashton Court PM

- 16/07/19 - Ashton Court PM

- 22/07/19 - Ashton Court PM

- 23/07/19 - Ashton Court AM

- 24/07/19 - Ashton Court PM

- 26/07/19 - Ashton Court PM

- 01/08/19 - Ashton Court AM

- 01/08/19 - Ashton Court PM

- 02/08/19 - Ashton Court AM

- 02/08/19 - Maize Field PM

- 13/08/19 - Ashton Court PM

- 15/08/19 - Pettefords Tether at Nailsea

- 20/08/19 - Ashton Court AM

- 20/08/19 - Royal Victoria Park PM

- 21/08/19 - Ashton Court AM

- 21/08/19 - Ashton Court PM

- 23/08/19 - Flight from Maize Field PM

- 23/08/19 - Ashton Court PM

- 25/08/19 - Maize Field AM

- 25/08/19 - Royal Victoria Park AM

- 25/08/19 - Ashton Court PM

- 26/08/19 - Ashton Court PM

- 01/09/19 - Ashton Court AM

- 07/09/19 - Keynsham AM

- 07/09/19 - Maize Field PM

- 08/09/19 - Ashton Court AM

- 08/09/19 - Timsbury Flyout PM

- 10/09/19 - Ashton Court AM

- 18/09/19 - Keynsham PM

- 19/09/19 - Maize Field PM

- 16/11/19 - G-BIRE Tether at Ashton Court

-

2018 Bristol & Bath Flights

>

- 06/03/18 - Ashton Court PM

- 21/03/18 - Ashton Court AM

- 25/03/18 - Ashton Court PM

- 26/03/18 - Ashton Court AM

- 05/04/18 - Test Inflations AM

- 19/04/18 - Ashton Court AM

- 19/04/18 - Ashton Court PM

- 20/04/18 - Maize Field PM

- Balloon Flight | 21/04/18 - Royal Victoria Park AM

- 03/05/18 - Ashton Court AM

- 03/05/18 - Ashton Court PM

- 04/05/18 - Chubb Special Shape Inflation | Ashton Court AM

- Balloon Flight | 04/05/18 - Ashton Court PM

- Balloon Flight | 05/05/18 - Maize Field AM

- 05/05/18 - Maize Field PM

- 05/05/18 - Ashton Court PM

- 06/05/18 - Maize Field AM

- 06/05/18 - Royal Victoria Park AM

- 06/05/18 - Ashton Court AM

- 06/05/18 - Maize Field PM

- 06/05/18 - Balloons over Bristol PM

- 07/05/18 - Maize Field AM

- 07/05/18 - Chew Magna Flyout PM

- 08/05/18 - Ashton Court AM

- 10/05/18 - Ashton Court PM

- 12/05/18 - Maize Field AM

- 12/05/18 - Ashton Court PM

- 13/05/18 - Ashton Court AM

- 13/05/18 - Portway Tether AM

- 14/05/18 - Ashton Court PM

- 17/05/18 - Royal Victoria Park PM

- 25/05/18 - Bath Balloon Fiesta PM

- 02/06/18 - Ashton Court PM

- 03/06/18 - Royal Victoria Park PM

- 03/06/18 - Maize Field PM

- 06/06/18 - Maize Field PM

- 08/06/18 - Maize Field PM

- 09/06/18 - Maize Field AM

- 09/06/18 - Maize Field PM

- 12/06/18 - Maize Field PM

- 13/06/18 - Ashton Court AM

- 15/06/18 - Ashton Court AM

- 22/06/18 - Ashton Court PM

- 22/06/18 - Didmarton Meet PM

- 23/06/18 - Didmarton Meet AM

- 25/06/18 - Royal Victoria Park PM

- 26/06/18 - Ashton Court AM

- 05/07/18 - Ashton Court AM

- 06/07/18 - Ashton Court PM

- 07/07/18 - Cheddar Rugby Club AM

- 07/07/18 - Ashton Court PM

- Balloon Flight | 08/07/18 - Maize Field AM

- 08/07/18 - South Gloucestershire PM

- 08/07/18 - Maize Field PM

- 10/07/18 - Royal Victoria Park PM

- 11/07/18 - Ashton Court AM

- 14/07/18 - Ashton Court AM

- 15/07/18 - Ashton Court AM

- 15/07/18 - Ashton Court PM

- 16/07/18 - Ashton Court AM

- 17/07/18 - Royal Victoria Park PM

- 18/07/18 - Ashton Court AM

- 18/07/18 - Ashton Court PM

- 19/07/18 - Ashton Court AM

- 19/07/18 - Ashton Court PM

- 21/07/18 - Ashton Court AM

- 21/07/18 - Ashton Court PM

- 22/07/18 - Keynsham AM

- 22/07/18 - Timsbury Flyout PM

- 25/07/18 - Ashton Court PM

- 02/08/18 - Ashton Court PM

- 03/08/18 - Ashton Court PM

- 04/08/18 - Ashton Court PM

- 05/08/18 - Ashton Court PM

- 07/08/18 - Ashton Court AM

- 09/08/18 - Pre Fiesta Flight | Ashton Court AM

- 21/08/18 - Ashton Court PM

- 28/08/18 - Bishop Sutton Flyout PM

- 30/08/18 - Ashton Court PM

- 31/08/18 - Maize Field PM

- 01/09/18 - Henbury AM

- 01/09/18 - Maize Field PM

- 02/09/18 - Tethering in Nailsea PM

- 02/09/18 - Ashton Court PM

- 05/09/18 - Maize Field PM

- 06/09/18 - Ashton Court AM

- 07/09/18 - Ashton Court AM

- 12/09/18 - Ashton Court PM

- 13/09/18 - Ashton Court AM

- 25/09/18 - Royal Victoria Park PM

- 26/09/18 - Ashton Court PM

- 29/09/18 - Ashton Court PM

- 05/10/18 - Ashton Court PM

- 07/10/18 - Ashton Court PM

- 19/10/18 - Maize Field PM

- 20/10/18 - Ashton Court PM

- 28/12/18 - Maize Field PM

-

2017 Bristol & Bath Flights

>

- 05/01/17 - Cash4Cars over Bristol

- 22/01/17 - Royal Victoria Park PM

- 18/02/17 - Ashton Court G-GAGE Tether

- 13/03/17 - Ashton Court AM

- Balloon Flight | 27/03/17 - Royal Victoria Park PM

- 02/04/17 - Keynsham AM

- 02/04/17 - Ashton Court PM

- 05/04/17 - Royal Victoria Park AM

- 05/04/17 - Royal Victoria Park PM

- 06/04/17 - Royal Victoria Park AM

- 06/04/17 - Maize Field PM

- 07/04/17 - Maize Field AM

- 07/04/17 - Ashton Court PM

- 08/04/17 - Royal Victoria Park AM

- 08/04/17 - Maize Field AM

- 08/04/17 - Royal Victoria Park PM

- 10/04/17 - Ashton Court PM

- 13/04/17 - Ashton Court AM

- 13/04/17 - Royal Victoria Park PM

- 17/04/17 - Royal Victoria Park AM

- 17/04/17 - Maize Field PM

- 18/04/17 - Keynsham PM

- 19/04/17 - Royal Victoria Park PM

- 22/04/17 - Maize Field PM

- 23/04/17 - Ashton Court PM

- 27/04/17 - Ashton Court AM

- 28/04/17 - Ashton Court PM

- Balloon Flight in G-UWEB | 29/04/17 - Maize Field AM

- 06/05/17 - Royal Victoria Park PM

- 07/05/17 - Maize Field AM

- 07/05/17 - Maize Field PM

- 09/05/17 - Royal Victoria Park PM

- 10/05/17 - Royal Victoria Park PM

- 24/05/17 - Royal Victoria Park PM

- Balloon Flight in Red Letter Days | 25/05/17 - Royal Victoria Park AM

- 28/05/17 - Ashton Court AM

- 28/05/17 - Maize Field AM

- 31/05/17 - Ashton Court Tether PM

- 13/06/17 - Ashton Court AM

- 13/06/17 - Keynsham PM

- 14/06/17 - Maize Field PM

- 14/06/17 - Royal Victoria Park PM

- 17/06/17 - Ashton Court PM

- 18/06/17 - Keynsham AM

- 18/06/17 - Ashton Court AM

- 18/06/17 - Tethering Bagerline - Ashton Court PM

- 19/06/17 - Maize Field PM

- 26/06/17 - Royal Victoria Park PM

- 02/07/17 - Ashton Court AM

- 04/07/17 - Ashton Court PM

- 04/07/17 - Fiesta Charity Partnership Launch | Ashton Court PM

- 05/07/17 - Royal Victoria Park PM

- 08/07/17 - Ashton Court PM

- 09/07/17 - Ashton Court AM

- 09/07/17 - Ashton Court PM

- 10/07/17 - College Green Tether AM

- 12/07/17 - Royal Victoria Park PM

- 12/07/17 - Maize Field PM

- 17/07/17 - Maize Field AM

- 17/07/17 - Royal Victoria Park PM

- 24/07/17 - Royal Victoria Park PM

- 25/07/17 - Royal Victoria Park AM

- 25/07/17 - Ashton Court PM

- 31/07/17 - Visit Bath Tether | Royal Crescent PM

- 01/08/17 - Ashton Court AM

- Balloon Flight in Tango | 06/08/17 - Ashton Court AM

- 20/08/17 - Ashton Court AM

- 21/08/17 - Ashton Court PM

- 24/08/17 - Ashton Court PM

- 25/08/17 - Ashton Court PM

- 26/08/17 - Ashton Court PM

- 27/08/17 - Ashton Court AM

- 27/08/17 - Ashton Court PM

- 28/08/17 - Ashton Court PM

- 01/09/17 - Ashton Court PM

- 01/09/17 - Bower Ashton PM

- 02/09/17 - Ashton Court PM

- 04/09/17 - Ashton Court PM

- 26/09/17 - Royal Victoria Park PM

- 08/10/17 - Ashton Court PM

-

2016 Bristol & Bath Flights

>

- 16/01/16 - Ashton Court PM

- 11/03/16 - Royal Victoria Park PM

- 12/03/16 - Royal Victoria Park AM

- 13/03/16 - Royal Victoria Park AM

- 18/03/16 - Royal Victoria Park AM

- 20/03/16 - Royal Victoria Park PM

- 21/03/16 - Royal Victoria Park AM

- 22/03/16 - Royal Victoria Park AM & Ashton Court PM

- 23/03/16 - Royal Victoria Park AM

- 25/03/16 - Ashton Court AM

- 25/03/16 - Ashton Court PM

- 17/04/16 - Ashton Court AM

- 17/04/16 - Ashton Court PM

- 28/04/16 - Ashton Court AM

- 30/04/16 - Ashton Court AM

- 03/05/16 - Ashton Court AM

- 05/05/16 - Royal Victoria Park PM

- 06/05/16 - Royal Victoria Park PM

- 14/05/16 - Ashton Court PM

- 14/05/16 - Maize Field PM

- 15/05/16 - Keynsham AM

- 22/05/16 - Ashton Court AM

- 04/06/16 - Royal Victoria Park PM

- 18/06/16 - Ashton Court AM

- 19/06/16 - Ashton Court AM

- 21/06/16 - Ashton Court PM

- 27/06/16 - Ashton Court PM

- 03/07/16 - Ashton Court AM

- 03/07/16 - Ashton Court PM

- 04/07/16 - Ashton Court AM

- 06/07/16 - Ashton Court AM

- 06/07/16 - Ashton Court PM

- 07/07/16 - Balloons over Bristol PM

- 14/07/16 - Ashton Court PM

- 17/07/16 - Ashton Court PM

- 18/07/16 - College Green & Ashton Court PM

- 18/07/16 - Maize Field PM

- 23/07/16 - Ashton Court AM

- 23/07/16 - Ashton Court PM

- 25/07/16 - Ashton Court AM

- 30/07/16 - Ashton Court PM

- 31/07/16 - Ashton Court AM

- 06/08/16 - Ashton Court AM

- 17/08/16 - Maize Field PM

- 26/08/16 - Ashton Court PM

- 29/08/16 - Ashton Court AM

- 29/08/16 - Ashton Court PM

- 30/08/16 - Ashton Court AM

- 30/08/16 - Ashton Court PM

- 31/08/16 - Ashton Court AM

- 14/09/16 - Royal Victoria Park PM

- 18/09/16 - Ashton Court PM

- 18/09/16 - Royal Victoria Park PM

- 20/09/16 - Maize Field PM

- 23/09/16 - Ashton Court AM

- 02/10/16 - Ashton Court PM

- 08/10/16 - Royal Victoria Park PM

- 27/12/16 - Ashton Court AM

-

2015 Bristol & Bath Flights

>

- 18/06/15 - Ashton Court PM

- 19/06/15 - Ashton Court AM

- 19/06/15 - Ashton Court PM

- 23/06/15 - Ashton Court PM

- 24/06/15 - Ashton Court PM

- 25/06/15 - Ashton Court AM

- 25/06/15 - Keynsham Rugby Football Club PM

- 27/06/15 - Ashton Court PM

- 29/06/15 - Maize Field, Royal Victoria Park & Keynsham Rugby Football Club PM

- 02/07/15 - Ashton Court PM

- 03/07/15 - Ashton Court AM

- 04/07/15 - Didmarton Flyout PM

- 05/07/15 - Didmarton Flyout AM

- 09/07/15 - Ashton Court PM

- 18/07/15 - Ashton Court PM

- 19/07/15 - Ashton Court PM

- 23/07/15 - Ashton Court AM

- 30/07/15 - Ashton Court PM

- 31/07/15 - Ashton Court PM

- 01/08/15 - Ashton Court AM

- 15/08/15 - Lloyds Amphitheatre AM

- 16/08/15 - Wickwar AM

- 16/08/15 - Royal Victoria Park PM

- 16/08/15 - Maize Field PM

- 06/09/15 - Maize Field AM

- 06/09/15 - Ashton Court PM

- 07/09/15 - Royal Victoria Park PM

- 17/09/15 - Ashton Gate Stadium PM

- 19/09/15 - Ashton Court PM

- 20/09/15 - Ashton Court PM

- 25/09/15 - Ashton Court AM

- 25/09/15 - Ashton Court PM

- 26/09/15 - Royal Victoria Park AM

- 02/10/15 - Royal Victoria Park PM

- 18/10/15 - Royal Victoria Park PM

- 20/10/15 - Ashton Court PM

- 25/10/15 - Ashton Court AM

- 25/10/15 - Keynsham RFC PM

-

2014 Bristol & Bath Flights

>

- 01/03/14 - Maize Field AM

- 05/03/14 - Ashton Court AM

- 09/03/14 - Lloyds Amphitheatre AM

- 01/04/14 - Royal Victoria Park PM

- 04/04/14 - Ashton Court PM

- 09/04/14 - Ashton Court PM

- 10/04/14 - Ashton Court AM

- 11/04/14 - Ashton Court PM

- 12/04/14 - Ashton Court AM

- 13/04/14 - Shirehampton AM

- 14/05/14 - Ashton Court PM

- 15/05/14 - G-BPGD Landing

- 16/05/14 - Ashton Court PM

- 17/05/14 - Ashton Court AM

- 17/05/14 - Ashton Court PM

- 31/05/14 - Shirehampton PM

- 01/06/14 - Ashton Court PM

- 03/06/14 - G-VBAE over Bristol

- 05/06/14 - Ashton Court PM

- 11/06/14 - Ashton Court PM

- 12/06/14 - Ashton Court PM

- 15/06/14 - Timsbury Flyout PM

- 20/06/14 - Ashton Court PM

- 21/06/14 - Maize Field AM

- 21/06/14 - Maize Field PM

- 22/06/14 - Maize Field + RVP AM

- 22/06/14 - Bishop Sutton Flyout PM

- 24/06/14 - Ashton Court PM

- 29/06/14 - Ashton Court PM

- 30/06/14 - Ashton Court AM

- 01/07/14 - Keynsham RFC PM

- 02/07/14 - Ashton Court PM

- 06/07/14 - WRBBAC Flyout AM

- 15/07/14 - Ashton Court PM

- 20/07/14 - Ashton Court AM

- 21/07/14 - Ashton Court AM

- 30/07/14 - Ashton Court AM

- 04/08/14 - Ashton Court AM

- 20/08/14 - Ashton Court PM

- 31/08/14 - Ashton Court AM

- 31/08/14 - Ashton Court PM

- 01/09/14 - Ashton Court PM

- 02/09/14 - Royal Victoria Park PM

- 07/09/14 - Maize Field PM

- 21/09/14 - Queen Square AM

- 22/09/14 - Ashton Court PM

- 26/09/14 - Ashton Court PM

- 06/12/14 - Ashton Court AM

- Other 2014 Photos

- 2013 Bristol & Bath Flights >

- Fiesta Programmes >

- Bath Balloon Fiesta

- Midlands Air Festival >

- Longleat Sky Safari >

- Telford Balloon Fiesta 2022

- Telford Balloon Fiesta 2021

- Icicle Refrozen Balloon Meet 2020

- Icicle Refrozen Balloon Meet 2019

- Yorkshire Balloon Fiesta 2022

-

Other Events

>

- Berkshire Balloon & Action Extravaganza 2022

- Cheltenham Balloon Fiesta 2022

- Springkle Balloon Meet 2022

- Streatley Night Glow 2021

- Abingdon Firework Festival 2019

- Wales Airshow Night Glow 2019

- Balloons on the Beach | Weston-super-Mare 2019

- Balloons on the Beach | Weston-super-Mare 2018

- BBM&L Inflation Days

- Tiverton Balloon Festival 2015

- Queens Cup Balloon Race 2013

- Fiesta Newspapers

- More Photos

-

Bristol Balloon Fiesta

>

- Blog

- Contact

- Online Shop